Our

IRM services can be extended into several areas including-

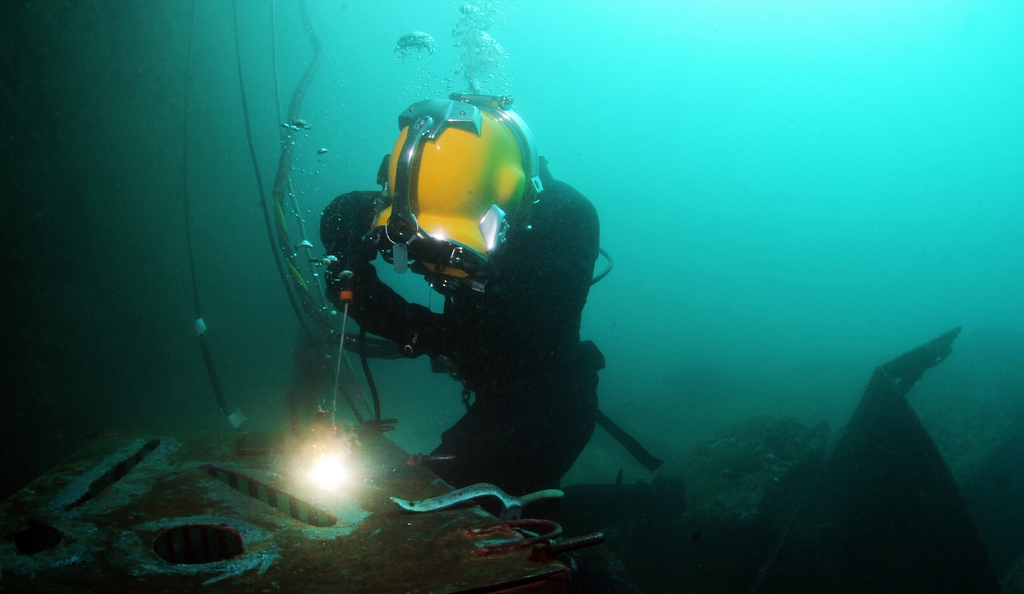

- Design, management, and execution of subsea repairs

- Rig positioning survey

- UWILD Survey, Underwater hull Inspection & Cleaning

- Ultrasonic Thickness Gauging

- Pipeline and platform inspection

- Anchor chain inspection and measurement

- Leak investigation and repair

- Pipeline stabilisation and repair using clamps and spools

- Anode clamp design and retrofit

- Cathodic protection – Measurement & Installation

- Structure & Pipeline repair clamp installation

- Pre and post-installation surveys

- Suction anchor installation

- Pipeline commissioning and testing

- Pipeline intervention and stabilisation

- Cable and pipeline trenching services

- Subsea tree/module installation and recovery

- ROV mounted tooling solutions specifically designed

- Subsea hardware component change-outs

- Installation of subsea isolation valve (SSIV)

- Installation of rigid/flexible risers and I / J Tubes

- Spool tie-ins And Hot taps

- Single Point Mooring (SPM) installation

- Pipeline End-Manifold (PLEM & PLET Lateral) installation

- Pipeline crossing and free-span correction

- Flow lines and umbilical installation support

- Trenching, backfill and out-of-straightness surveys

- Subsea hydro-testing

- Pre-installation crossing structure and survey

- Subsea excavation And Site Clearance survey

- Anode retrofit and life extension construction tasks

- Protection and stabilisation structures

- Subsea riser and mid-water arch operations

- Jack-up spud can survey

- Debris clearance survey and removal

- Platform and vessel inspection

- Structure cleaning

- Wet Welding & cutting

- Splash-zone survey and protection

- ROV mounted tooling solutions

- Non Destructive Testing (NDT) - ACFM, MPI, UT